Schumacher

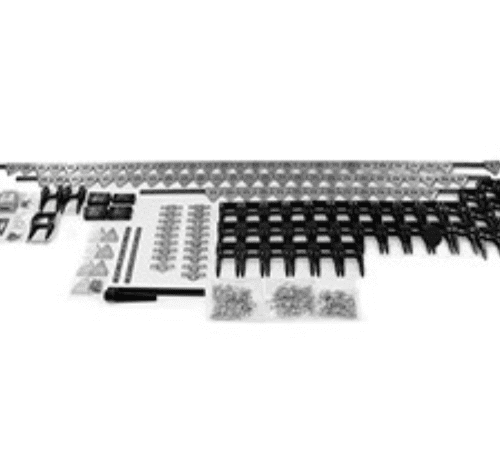

The Universal Cutting system

About

Cutterbars

Schumacher

Easy Cut II

Despite all technological advances around the combine and platform, the cutting system is still the first part to touch your crop and determines your harvest success. Based on this fact, we developed a superior cutting system with state of the art technology and quality.

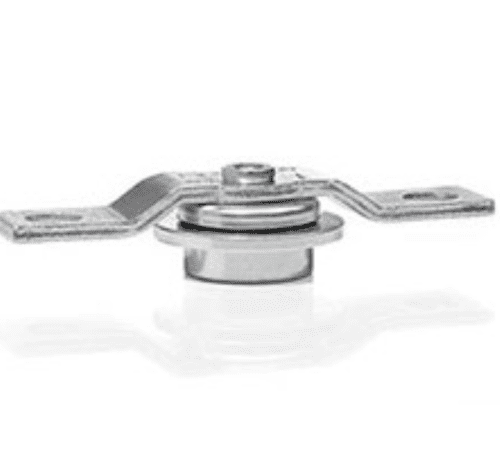

SCH roller guides: reduce friction, wear, and cost.

The width of combine platforms has increased substantially in the past years. Therefore, the total of the frictional forces has increased dramatically.

With the use of roller guides, we greatly improved the cutting system.

Change your cutting system to a Schumacher Cutterbar! …it’s just that easy to fill your grain tank.

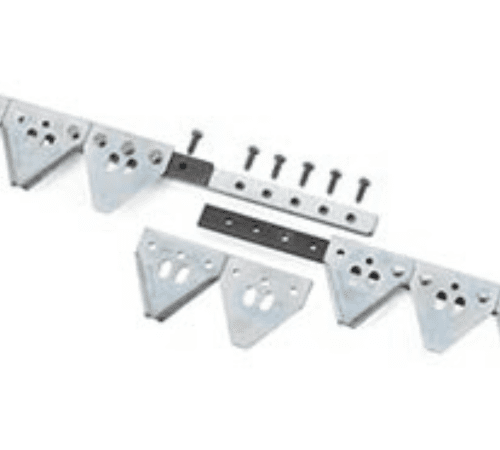

Schumacher

Easy Cut II GUARD

In the last decades, two types of double guards became dominate in the market: the forged guards and the Schumacher steel guard. What makes the SCH Easy Cut steel guard so special? The SCH Easy Cut guard is manufactured using a special alloy steel. A subsequent special hardening process gives the guard extremely high hardness, durability, and wear life. Another advantage is the much higher vertical and lateral strength of the guard. No guard lips break off; guards don’t bend. The angled cutting edges of the guard hold the crop material better, resulting in a cleaner cut and a better flow of the material. This also results in less power needed to cut the material.

- Quality spring steel material

- Special hardening for extremely hard & wear resistant surface, resulting in long wear life

- Features two cutting edges

- Bolted top & bottom gives protection from impact from all sides

Schumacher

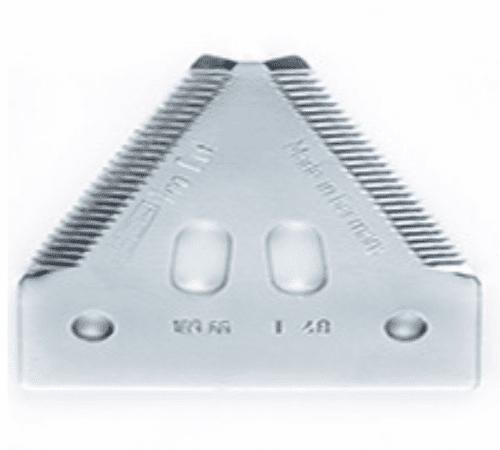

Easy Cut II PRO CUT SECTION

Stones and dirt are tough on knife sections. They not only increase section wear but can also damage other parts of the platform. Knife section quality is therefore of extreme importance.

Schumacher Pro Cut knife sections are completely thru-hardened, therefore extremely tough.

They don´t bend; they break. Therefore, when hitting large stones or other objects, damage to guards is eliminated which is not the case with regular sections.

The sections are fastened to the knifeback with a special serrated bolt and a flange nut. The conically shaped and serrated body of the bolt locks tightly in the section and knifeback hole. A tight and secure connection is the result. At the same time sections can be quickly changed.

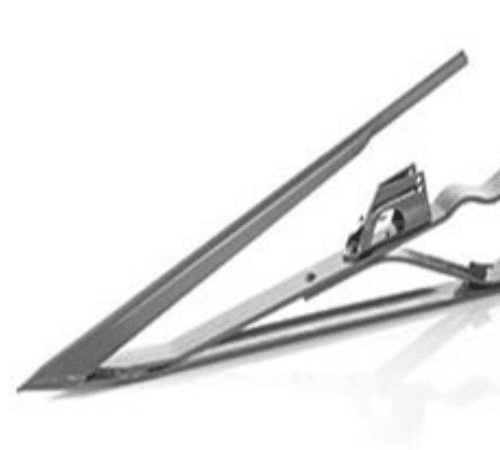

Standard Croplifter

Schumacher Croplifters

- Made of high quality spring steel

- Available to fit most North American guards

- Used in all small grain crops, canola & milo

- New generation lifters offer less wear on bottom runners (ASK)

- Simple on and off mounting